Our Client tasked Arthian with an ambitious goal: to design and deliver a 100 mbar blast-rated laboratory building. The structure needed to combine resilience with functionality, housing 17 precision-engineered steel modules and creating 560 m² of high-performance space for critical operations. Inside, the facility would include a laboratory, control room, feed area, and plant room, all supported by “shelter-in-place” capability to safeguard personnel during extreme events.

Adjacent to the main building, Arthian also had to design a six-module non-blast mezzanine, providing essential access and support for HVAC systems, an integral component for maintaining operational integrity.

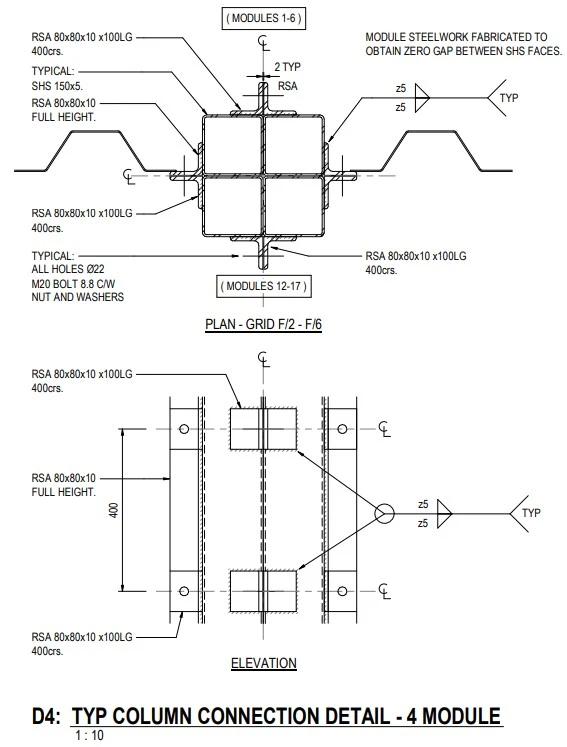

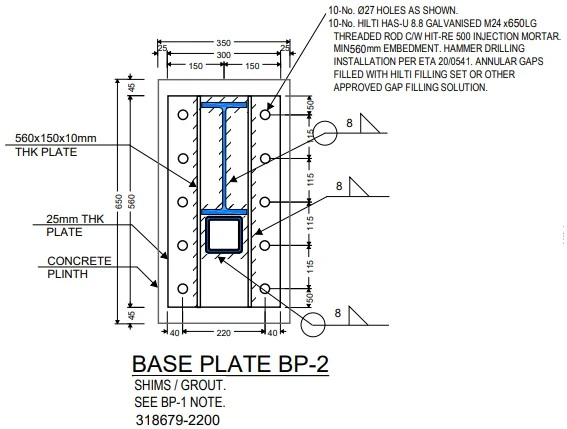

The scope was extensive: superstructure design for all modules, performance specifications for doors and windows, lifting analysis, hold-down, transit frames, and a robust substructure design incorporating piles, pile caps, and ground beams. To bring this vision to life, Arthian developed a full structural Revit model, complete with general arrangement and detailed drawings for steelwork and foundations. Adding to the complexity, the site itself posed considerable challenges. Located on a brownfield plot, it presented poor ground conditions, existing buried services, and tight spatial constraints. Additionally the requirement for large open spans of 12.15 m meant the roof structure and its connections demanded exceptional precision and strength.

The Solution

To ensure the building met the demanding blast-resistance requirements, Arthian adopted a single-degree-of-freedom analysis approach aligned with industry best practice and leading standards, including ASCE and PIP STC01018.

Working in close partnership with Integra’s architectural, mechanical, and electrical teams, Arthian delivered a fully coordinated superstructure and substructure design. By leveraging Revit and adopting a modular steel construction strategy, the team enabled faster fabrication, improved quality control, and a highly efficient construction programme.

Arthian also collaborated with specialist suppliers of blast-resistant doors, windows, dampers, and louvres, ensuring the facility delivers reliable, high-performance protection and long-term resilience.

Challenging ground conditions required a strategic foundation solution. Drawing on multidisciplinary expertise, Arthian identified the need for piled foundations and developed a comprehensive preliminary design. The Geotechnical and Structural teams worked together to optimise pile locations, prepare specifications, review the contractor’s design, and navigate constraints such as land availability, buried services, and civil-works requirements ensuring a safe and buildable solution.

From concept to completion, Arthian acted as a trusted engineering partner, driving the project forward and hitting every programme milestone. The team adapted seamlessly to fabrication priorities and construction sequencing requirements, ensuring progress never stalled.

On site, Arthian delivered hands-on technical assurance, supported the substructure contractor, and rigorously reviewed fabrication drawings to guarantee quality and compliance at every stage. This proactive approach kept the build aligned with specifications and safeguarded performance under challenging conditions. Through this collaborative, integrated, and quality-driven approach, Arthian helped deliver a facility that meets stringent safety demands, optimises build efficiency, and provides long-term operational reliability.

As of late 2025, modular fabrication is underway and groundworks construction is complete.

Our Latest Projects

Get in Touch

We’d love to hear from you – whether you have a question, a project in mind, want to explore job opportunities, or just want to say hello.